rockwell hardness test on carbon steel|how to calculate rockwell hardness : wholesalers This table shows approximate hardness of steel using Brinell, Rockwell B and C . WEB1 de dez. de 2023 · ioredis 可以兼容火山引擎 Redis,出现 ClusterAllFailedError: Failed to refresh slots cache 报错通常有如下两类场景: 密码错误:在连接时指定的密码错误,导致无法客户端无法连接到 Redis 分片集群 网络连通性:需要保证客户端与 Redis Cluster 的网 .

{plog:ftitle_list}

web16 de fev. de 2024 · Farm. Farm! Descriptions: Scarecrows as far as the eye can see! Reasons to come here: Farm is the most wonderful place to level up and get quest that give you nice amounts of gold and even RC coins! But be cautious, the scarecrows are alive! Monsters: Mosquito (lvl 2), Scarecrow (lvl 2), Treeant (lvl 2) NPC'S: Farmer Girl (quest .

The Rockwell scale is a hardness scale based on indentation .

This table shows approximate hardness of steel using Brinell, Rockwell B and C .

rockwell hardness testing chart

rockwell hardness tester diagram

Rockwell Hardness Testing Reference Guide. ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your . Rockwell hardness is expressed in three scales: HRA: Uses a 60kg load and a diamond cone indenter, suitable for extremely hard materials like hard alloys. HRB: Uses a 100kg load and a 1.58mm diameter hardened steel .The use of tungsten carbide balls will provide an improvement to the Rockwell hardness test because of the tendency of steel balls to flatten with use, which results in an erroneously .In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors .

The most straightforward answer is that Rockwell hardness refers to how resistant a metal object such as a knife blade is to penetration and permanent deformation from another material. It’s a measuring system of non-destructive . This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including aluminum, copper alloys, brass, soft steels, and hard .Brinell hardness of low-carbon steel is approximately 120 MPa. In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching. . that has been developed for hardness testing. . (e.g. Brinell, Knoop, Vickers and Rockwell). There are tables that are available correlating the .Hardness Testing Hardness testing can best be described as a measurement of “resistance to penetration” to a defined load. Several types or methods of hardness testing are more common and found in this table. . Carbon Steel .

Brinell hardness of high-carbon steel is approximately 200 MPa. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the .Reference Table: Steel hardness conversion chart - all values approximate. Brinell Hardness HB Rockwell HRC Rockwell HRB Vickers HV N/mm²; 800: 72---780: 71Get all the information you need on hardness testing and hardness test methods from ZwickRoell! Definition Examples Products for hardness testing More information. . (hardened steel, hard metal or diamond) Size of the test load applied to a specimen; . Rockwell; Carbon testing; Plastics testing; Test load. 0.3 - 250 kg; 3 - 3,000 kg; Versions.

Carbon Steel: Carbon Steel | EN8 | 1.0503 | Fe. As machined. Heat Treated . The Rockwell hardness test is based on the indentation depth caused by a diamond or a ball indenter under different loads. There are two main scales used in the Rockwell test: the Rockwell HRC scale (uses a diamond cone indenter) for harder materials and the Rockwell .Applications for Rockwell Methods The Rockwell hardness test is widely used in various industrial applications, such as manufacturing, engineering, and quality . including low-carbon steels, aluminum, lead, copper, and some plastics. The use of a large indenter . Steel/Iron Light Metal Copper Aluminium Light Metal Copper Aluminium Light .Low-carbon steel contains approximately 0.05–0.25% carbon making it malleable and ductile. Mild steel has a relatively low tensile strength, but it is cheap and easy to form; surface hardness can be increased through carburizing. . Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for .

Datasheet for Steel Grades Carbon Steel ASTM A36 ASTM A36 Standard Number: ITEM Standard Number Descriptions . Hardness, Brinell 119 - 159 119 - 159 based on conversion from tensile strength Hardness, Rockwell B 67.0 - 83.0 67.0 - 83.0 based on conversion from tensile strength Tensile Strength at BreakThese approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion TableLow-carbon steel contains approximately 0.05–0.25% carbon making it malleable and ductile. Mild steel has a relatively low tensile strength, but it is cheap and easy to form; surface hardness can be increased through carburizing. Hardness of Low-carbon Steel – ASTM A36. Brinell hardness of low-carbon steel is approximately 120 MPa. Carbon steel hardness rockwell(HR) test, when the sample is too small or the Brinell hardness (HB) is greater than 450, it is measured by rockwell hardness. The test method is to use a diamond cone with a apex angle of 120 degrees or a steel ball with a diameter of 1.5875mm/3.175mm/ 6.35mm/12.7mm, and press it into the surface of the material .

rockwell hardness test theory

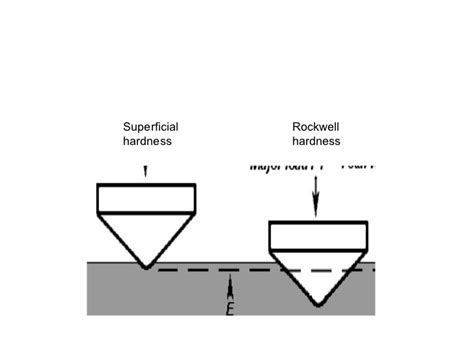

A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N. Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .The procedure for carbon testing is based on the Rockwell method. The hardness testing method in this case is also static, with similar characteristics to the Rockwell method: The procedure is standardised (DIN 51917, ASTM C886). Hardness is tested in the macro range with this method, with a test force between 29.42 and 1471 N. Vickers Hardness; Rockwell Hardness; A plain carbon steel and an alloy steel were assessed using the Jominy end quench test. The hardness of the samples was measured as a function of the distance from the quenched end to demonstrate the different hardenability of the two steels. The data is shown as Vickers and Rockwell hardness.Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale.Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. If a file cannot scratch your material, then your material is harder than the file.

Because of its low force, high speed, and nondestructive nature, Rockwell hardness testing commonly is used on all sizes of tubing. To perform a Rockwell test successfully, you must consider several factors. Surface .It’s most commonly used to check the hardness of steel that’s been heat treated. Here’s the process: How to Use a Rockwell Testing Machine. . You can’t use the Rockwell method for testing the hardness of .020″ shim stock if it’s supposed to be 60 HRC. Just be aware that there are minimum thicknesses in the 0.040″ and under range .

The AISI 1010 carbon steel is a plain carbon steel with 0.10% carbon content. This steel has relatively low strength but it can be quenched and tempered to increase strength. . Hardness, Rockwell B (converted from Brinell hardness) 60: 60: . Mechanical & Physical Properties Testing (Subscribe or Preview) See all Newsletters » . .

hardness tests - the Rockwell test is a measure of the resistance of material, specifically metals, to permanent indentation. Indentation hardness is not a fundamental . Rockwell C scale test on hardened steel, for example, penetrates to a depth of approximately 0.0035 inch, with the diameter of the indentation only 0.019 inch, which is The Rockwell hardness test uses three different test forces and three different indenters, resulting in a total of nine possible combinations and corresponding Rockwell hardness scales. . Quenching: For general medium carbon steel and high carbon steel, the hardness can be improved through quenching. Quenching is a common heat treatment .Low-carbon steel contains approximately 0.05–0.25% carbon making it malleable and ductile. . that has been developed for hardness testing. . Vickers and Rockwell). There are tables that are available correlating the hardness numbers from the different test methods where correlation is applicable. In all scales, a high hardness number .The following table shows AISI 4140 steel heat treatment, Rockwell hardness. Material 4140 Heat Treat: Temperature, °C (°F) 4140 steel hardness: Cooling/Agent: Normalizing: 870 (1600) 302 HB: Air: Annealing: 790-845 (1455-1555) . Carbon Steel; Stainless Steel; Alloy Steel; Aluminum Alloy; Tool Steel;

The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters. The surface of the sample was ground using a grinder to ensure it was flat and smooth. The B scale was selected, and the instrument was calibrated using a standard hardness block. The Rockwell hardness test was performed in accordance with the requirements of GB/T 230.1-2018 Metallic Materials Rockwell Hardness Test Part 1: Test Method. The most commonly used techniques include the Vickers hardness test, Rockwell hardness test, and Knoop hardness test. Vickers Hardness Test: . Density: Similar to high-carbon steel, around 7.85 g/cm³; Hardness: Typically between 600 and 900 HV, depending on composition and treatment;

Hardness • Brinell Hardness Test: 10mm diameter ball with a load of 500, 1000 or 3000kg • Rockwell Hardness Test: A cone shape indenter; the depth of penetration is measured. • Vickers Hardness Test: Pyramid shape indenter ()( 2 2 ) 2 Db Db Db Di F HB − − = π 2 1.854 D F HV =

rockwell hardness test pdf

rockwell hardness test explained

rockwell hardness scale chart

mohs scale of hardness chart

WEB22 de fev. de 2024 · 2 meanings: 1. a legally recognized relationship existing between two parties, such as that between lessor and lessee and.. Click for more definitions.

rockwell hardness test on carbon steel|how to calculate rockwell hardness